Outside view of completed gate.

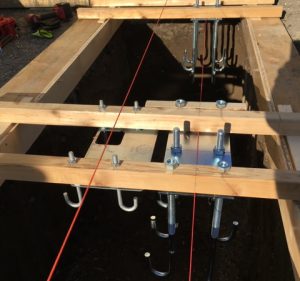

Reinforced foundation frame with J-Bolts tie rods to hold carriage foundation plates, conduit to run power to the gate operator.

String lines are used to ensure the gate frame will run parallel to the fence line.

Cured cement pad ready for mounting the cantilever carriages.

Steel fence posts mounted onto cement pads.

Gear rack connection welded to track.

Welding CGS-346P Bottom End Cup to fence post.

Welding eye loop to gate frame to hold bracing wire.

Bracing wire installed and gate no longer sags.

Close up view of top eye loop and bracing wire.

Outside view of finished gate and fence installation.

View of BFT ARES gate operator, protected by gate post.

Ghost gives his approval to this DuraGates installation.

Our client up in British Columbia shared his DuraGates hardware installation from start to finish. This midsize gate, 16FT x 700LBS, uses Model CGS-250.8P. The gate is automated using a BFT ARES rack & pinion slide gate operator. The wire bracing helps keep the gate level and prevent sagging. The "job foreman" in the photo is Ghost.

Recent Comments